3 steps to optimize the performance of a photovoltaic system

Despite excellent technology, no system is fail-safe. This is where commissioning comes into play, creating a basis for operating characteristics that is accepted by customers and used for subsequent maintenance. Commissioning is important not only for the performance of the photovoltaic (PV) system, but also for the longevity of the system, safety, return on investment and warranty.

Step 1: Planning and production of photovoltaic systems

To determine the production to be expected at your site, determine the amount of sunlight and take into account the shading that could occur with the modules. Solar radiation is measured in full hours of sunlight, which is the number of hours your system generates 1000W per square meter. For example, in many parts of California, solar radiation is excellent: 6000 W per square meter, or 6 full hours of sunshine. To determine the actual irradiance (watts/m2) and shading at your site, use the Fluke IRR-1 irradiance meter to determine reference values.

Suppose you have a PV system with 10 kW. You can calculate the expected annual production under the conditions mentioned in California by multiplying: 10 kW system x 6 full hours of sunlight x 365 days per year x 0.85 (15% power loss due to power losses in lines and inverters). This plant was to produce 18,615 kWh of usable energy per year or 51 kWh/day.

Step 2: Measure the performance of PV systems

After installing the system, ensure that it is working as intended by measuring the electrical characteristics and the actual output power of the modules.

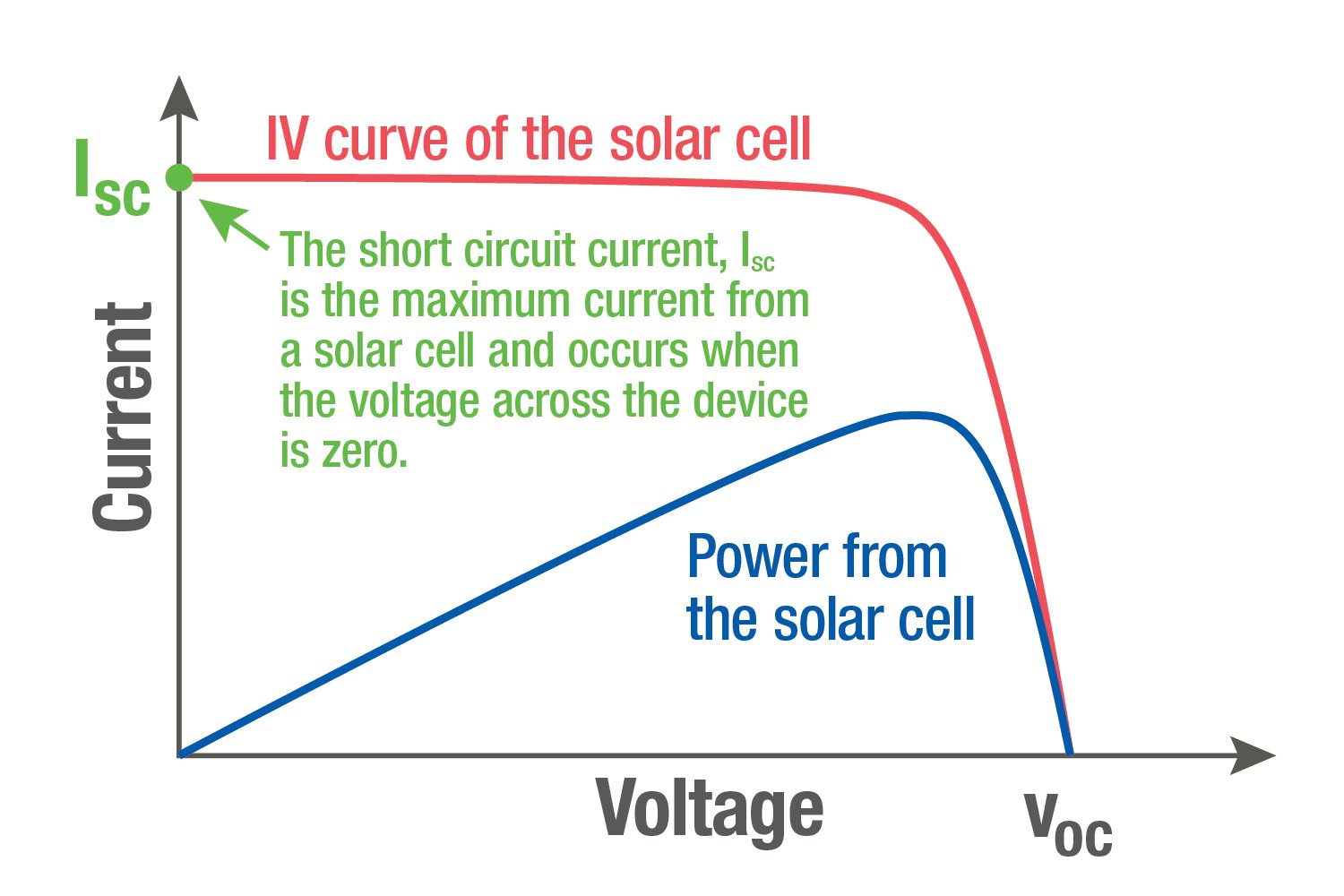

The output of a PV system is calculated on its current/voltage curve (IV curve). An inverter not only converts direct current to alternating current, but maximizes its output power by sensing the current and voltage – since power is voltage x current – where the string generates the most power. The short-circuit current (Isc) is the maximum current provided by a cell. No power is generated because there is no voltage difference: the positive and negative lines touch each other. The open-circuit voltage (Voc) is the maximum voltage provided by a cell: no power is generated because the circuit is broken. The point at which the module generates the most power is called the maximum power point (mpp).

Current-voltage characteristic curve (IV curve) of a PV module

To know if a system is working as intended, you need to know the values for Voc and Isc given on the module data sheet. Measure Voc and Isc before and after installation.

Voc is measured using the Fluke 393 FC with CAT III clamp meter to determine the voltage between the positive and negative terminals. The 393 FC offers the highest level of safety according to the measurement categories CAT III 1500 V/CAT IV 600 V and is therefore ideal for measurements in CAT III environments up to 1500 V, such as modern solar systems. Use the Fluke 64 MAX IR Thermometer to determine the temperature of the module to account for the influence of temperature on VOC (the lower the temperature, the higher the voltage, and vice versa). The 393 FC issues an audio polarity warning when testing Voc. If polarity is incorrect, the junction box or other circuitry can be unintentionally connected in series, resulting in voltages above the inverter's maximum input voltage.

The Fluke 393 FC is the world's only clamp meter with safety according to the CAT III 1500 V measurement category, ensuring safe and reliable use in solar systems.

To test ISC, disconnect all parallel circuits and safely short-circuit the circuit. Measure the current between the positive and negative terminals with a multimeter. Set the regulator to a current value greater than what you expect. Enter Isc and Voc values in the Fluke Connect™ app and save them for trend analysis and reporting

Check the insulation resistance of your conductors, connections between modules and between modules and racks, and ground resistance. Use the Fluke 1630-2 FC Earth Loop Meter to measure ground resistance to ensure a resistance of less than 25 ohms.

Step 3: Identify variances

Even if installed correctly, a PV system may not produce the expected electrical output. For a module, it is essential to specify the electrical characteristics, as an inverter has a minimum and maximum input current, below and above which it does not provide power at the output.

Scenario 1: Open circuit voltage or short-circuit current is higher or lower than indicated on the datasheet

In this case, your string includes one or more modules whose properties do not meet specifications. An open-circuit voltage outside the allowable range means that the inverter may not provide output power. A short-circuit current outside the allowable range indicates that modules may not match each other. This can significantly affect the performance of your system, as the current of a string is limited by the module with the lowest current. Identify and replace the modules.

The Fluke 393 FC can measure voltage, current and DC voltage and provides an audible warning signal in the event of incorrect polarity of PV modules.

Scenario 2: Low Output Power

If you find that the output power is lower than expected, there may be a problem. Although some fluctuations in performance are to be expected, a consistently lower performance than expected could be a sign of a defective string, a grounding fault or shading.

One reason could be a short-circuited cell. Here, electricity can no longer flow, which can lead to reduced performance, overheating and possibly a fire. Thermal imaging cameras such as the Fluke Ti480 PRO or the TiS75+ can quickly detect hot spots.

Grounding faults are another reason. However, these are more difficult to determine and require testing the voltage and current of each conductor, as well as the equipment grounding conductor that transmits stray current to the ground. Voltage and current on the device grounding conductor indicate a grounding fault. Grounding faults can occur due to damaged conductor insulation, improper installation, pinched wires, and water, which can create an electrical connection between a conductor and the equipment grounding conductor. Identify the cause of the problem and replace the damaged cables or create improved conditions.

Other reasons for low output power can include shading, as well as poor alignment of the tilt and side angles to your location. Use a Solar Pathfinder to find new causes of shading and eliminate them if possible. While it is not possible to adjust the alignment of the plant's tilt and side angles to align the modules more directly with the sun, you should know the tilt and side angles to establish a base as a future reference.

In large PV systems, after being inverted, the energy from a solar system flows through transformers to increase voltage, and then to switchgear and medium-voltage cables, where reduced insulation resistance is a common problem. For medium and high voltage cables, use the Fluke 1555 FC 10 kV insulation meter, which can measure up to 10,000 volts.

For battery-powered systems, compare the expected battery voltage and state of charge with the actual value with the Fluke 500 Series Battery Tester.